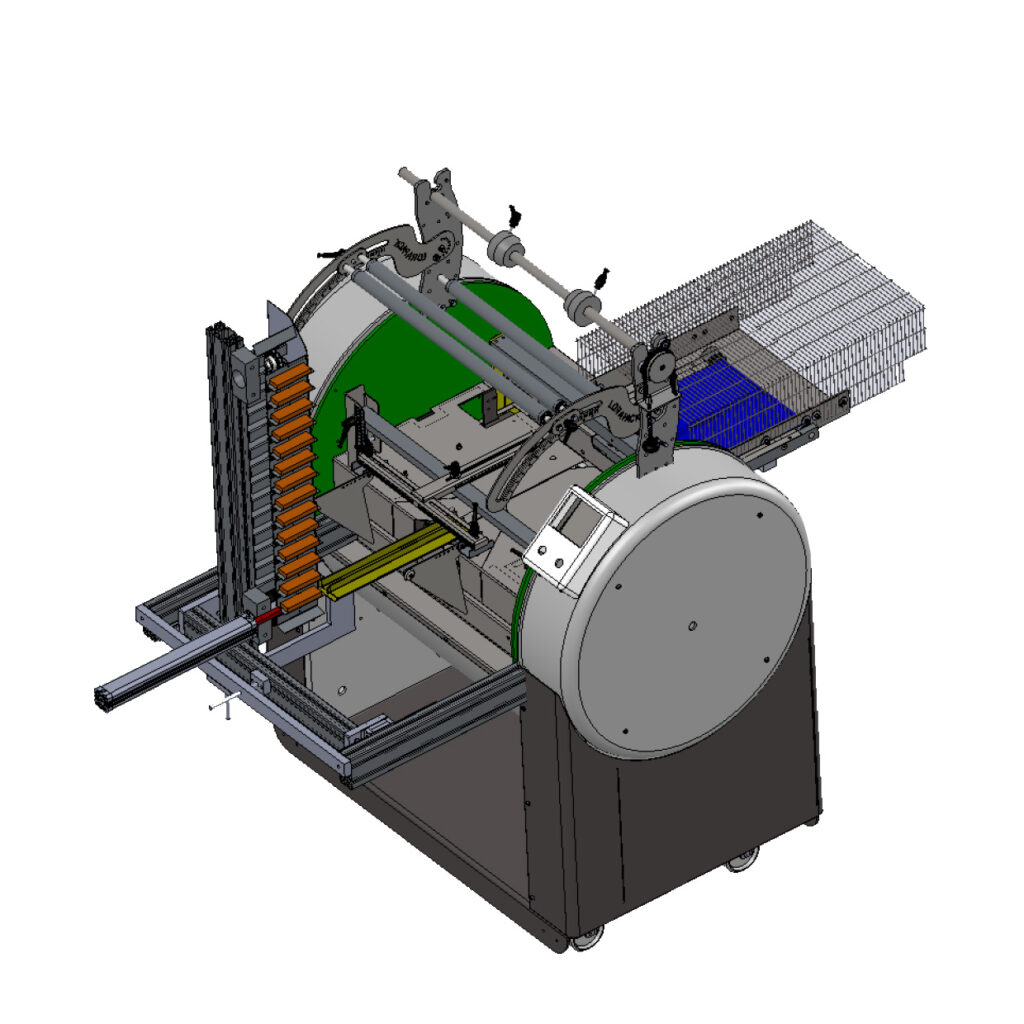

Compact packaging machine for food bars

Up to 30 bars can fit on the “loader” feeding system.

System composed of a support quadrilateral installed on the feeding front of the machine and a vertical feeding structure of the system itself.

Up to 30 bars can be placed on the “loader” feeding system which will then be automatically brought to the beginning of the forming tunnel thanks to an electric motor which gradually lowers the product to bring it into position.

A pneumatic cylinder provides for the insertion of the product, avoiding problems of contact or sticking of the product with the film.

FAQ

The range of products that can be packaged with the patented Lorapack machines is potentially infinite: meat; fruit and vegetables; bakery and pastry products; technical, textile and hardware products; hobby and do-it-yourself products; picture frames; wooden profiles; home accessories (handles, curtain poles, etc.).

You can package products in bulk or in trays (such as cheese, berries, cherry tomatoes), and even disposable place settings for restaurants and pizzerias (bag with cutlery and paper napkin inside). The maximum dimensions of the product are conditioned only by the size of the film reel you choose to use.

However, it is not recommended to use Lorapack packaging machines to package: fragile materials (glass, ceramic); products containing a lot of liquids (juices, sauces, mozzarella with liquid); very fine powders (flours, yeast, talc)

All heat-sealable films can be used, such as polythene, polypropylene, polyester, laminated films and even biodegradable and compostable materials.

The difference is speed, much greater in CRIMA FAST. Thanks to the presence of the loading belt, which is standard for this machine, and the translating cutting and sealing jaws, CRIMA FAST is able to increase the speed of packaging, reaching up to 50 packages per minute.

Subsequently, it is sufficient to move the loading belt and CRIMA FAST is able to work with the same degrees of inclination as a traditional CRIMA.

All the machines, with the exception of the EASY CRIMA, are compatible for modified atmosphere packaging, with alcohol or gas.

Given the small size and not very high speed of EASY CRIMA, the addition of modified atmosphere packaging would further slow down the work, and is therefore not recommended.

No, Lorapack machines require very little technical assistance, as they are easy to use. If necessary, it may be sufficient to request technical assistance via telephone.

Naturally, to prevent the machinery from having problems, it is necessary to carry out normal cleaning actions at the end of the production cycle.

Sure! If the environment in which the Lorapack machine is used is humid, or if barrel washing is used, it is possible to request that the machine be made of stainless steel.

For the first few times when you are not yet familiar with it, it takes 5, 6 minutes to change a reel. Once you’re familiar with it, it takes about 1 and a half minutes.

The machines use flat sheet films; not single-fold or tubular films.

ARE YOU LOOKING FOR AN EASY-TO-USE AND EFFICIENT PACKAGING MACHINE?

Contact us now for a free consultation